AW: Titanium Brake Rotors

Hmm, sorry but is the use of titanium for a brake rotor a good idea?

from

http://en.wikipedia.org/wiki/Titanium :

A metallic element, titanium is recognized for its high strength-to-weight ratio.It is a light, strong metal with low density that, when pure, is quite ductile (especially in an oxygen-free environment), lustrous, and metallic-white in color. The relatively high melting point (over 1,649 °C or 3,000 °F) makes it useful as a refractory metal.

Commercial (99.2% pure) grades of titanium have ultimate tensile strengths of about 63,000 psi, equal to that of steels alloys, but are 45% lighter. Titanium is 60% heavier than aluminium, but more than twice as strong as the most commonly used 6061-T6 aluminium alloy. Certain titanium alloys (e.g., Beta C) achieve tensile strengths of over 200,000 psi (1.4 GPa).

However, titanium loses strength when heated above 430 °C (800 °F).

It is fairly hard (although not as hard as some grades of heat-treated steel) and is difficult to machine, as it will gall if sharp tools and proper cooling methods are not used. Like those made from steel, titanium structures have a fatigue limit which guarantees longevity in some applications.

The metal is a dimorphic allotrope with the hexagonal alpha form changing into the body-centered cubic (lattice) beta form at 882 °C (1,619 °F).[5] The heat capacity of the alpha form increases dramatically as it is heated to this transition temperature but then falls and remains fairly constant for the beta form regardless of temperature.

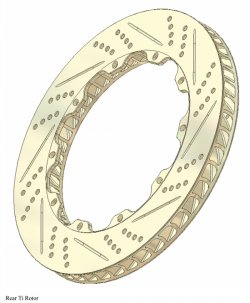

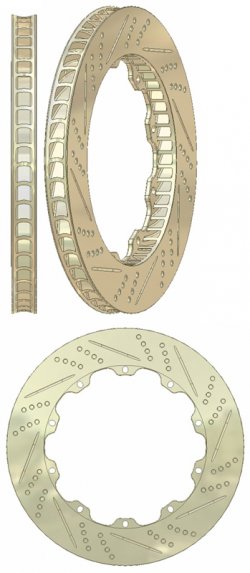

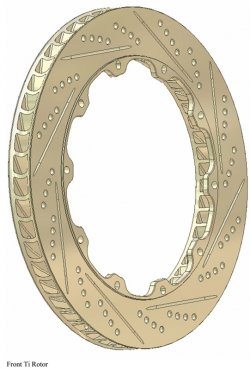

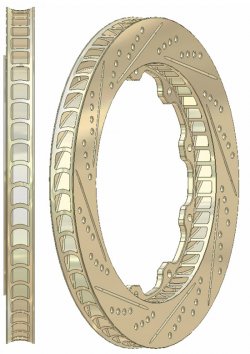

er (2.72 kg to 3.17 kg). Of course, the new rotors will work with the Brembo bells (hats).

er (2.72 kg to 3.17 kg). Of course, the new rotors will work with the Brembo bells (hats). er (2.72 kg to 3.17 kg). Of course, the new rotors will work with the Brembo bells (hats).

er (2.72 kg to 3.17 kg). Of course, the new rotors will work with the Brembo bells (hats).